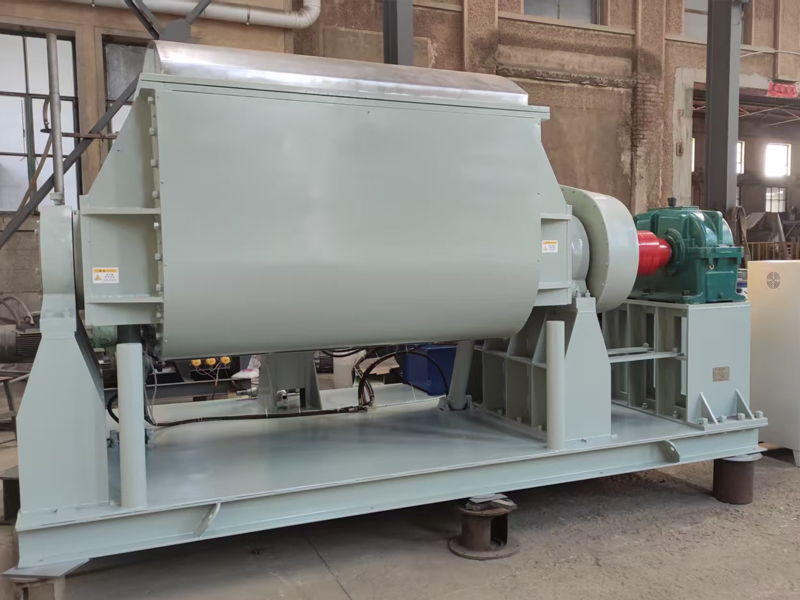

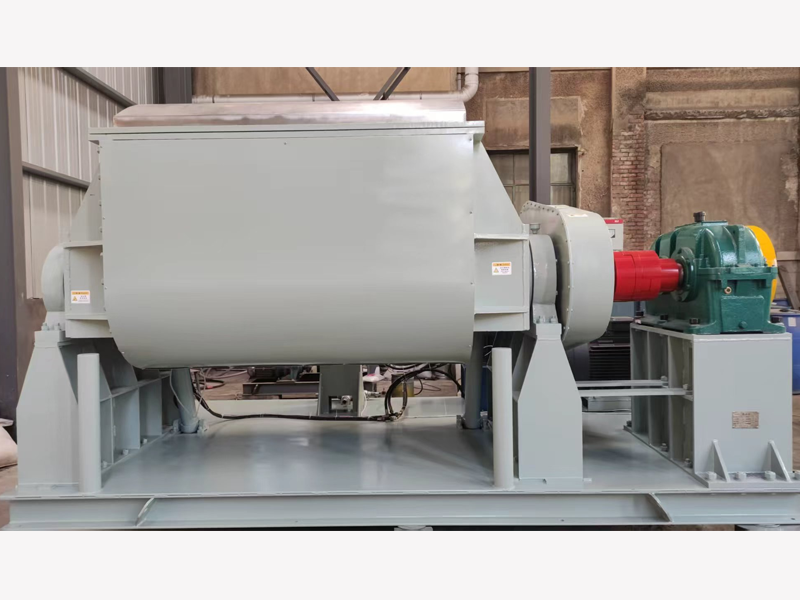

Stainless steel kneading

Stainless steel kneading machine is an industrial equipment used for mixing high viscosity materials such as pigments, dyes, pharmaceuticals, silicone gel, and foaming glue. Its applications cover the fields of sealant, rubber, cosmetics, and chemical material processing.

The equipment is divided into four types according to its structure: ordinary type, pressure type, vacuum type, and high temperature type. The cylinder body and blades are made of stainless steel or special alloy materials. Equipped with jacket, steam, heat transfer oil heating and water cooling temperature control system, the discharge methods include hydraulic cylinder flipping, pouring, discharge and screw extrusion. The mixing blade is equipped with four types: fish tail type, Z-type, cutting type, and ∑ type, which are suitable for the kneading, dispersion, and dehydration needs of materials with different viscosities. Some models are equipped with PLC control systems that can monitor temperature, time, and viscosity parameters, with a volume range of 5-3000L and a driving power of 2.2-190kW.

Technical parameters of kneader |

|||||||||||

| Model | JR5L | JR10L | JR100L | JR300L | JR500L | JR1000L | JR1500L | JR2000L | JR3000L | JR4000L | JR5000L |

| Volume | 5L | 10L | 100L | 300L | 500L | 1000L | 1500L | 2000L | 3000L | 4000L | 5000L |

| Heating method | 1. Thermal oil heating 2.electric heating 3. steam heating | ||||||||||

| Host power(KW) | 0.75-1.5KW | 1.5-3KW | 4-11KW | 5.5-22KW | 11-45KW | 18.5-75KW | 45-90KW | 45-160KW | 45-160KW | 55-280KW | 90-355 |

| Screw motor power | 3—5.5 | 4—11 | 5.5—15 | 7.5—18.5 | 11—22 | 15—37 | 18.5—45 | 18.5—45 | 18.5—45 | ||

| Electric heating power | 1.8 | 4.2 | 12 | 18 | 36 | 45 | 54 | 72-84 | Can be customized according to temperature | ||

| vapor pressure | 0.2-0.4 | ||||||||||

| Load factor | ≦70% | ||||||||||

| Speed | 41/26 | 41/26 | 36/22 | 36/22 | 36/25 | 36/25 | 36/25 | 30/22 | 30/22 | 27/22 | |

| Degree of vacuum | ≦0.095Mpa | ||||||||||

| Discharge method | 1. Turning cylinder discharge, 2. Screw discharge, 3. Bottom discharge | 1. Screw discharge 2. lower discharge | |||||||||

| Equipment weight | 210-300 | 250-340 | 1100-1250 | 2000-2500 | 2800-3800 | 4200-4600 | 5200-5500 | 6400-6800 | 9000-9500 | 10000-11000 | 11000-13000 |

| Remarks | 1. Industry parameters are based on conventional design; 2. Customized according to material characteristics | ||||||||||

Message

Fill in your phone and email information, and we will contact you promptly to resolve your issue as soon as possible

中文

中文 English

English