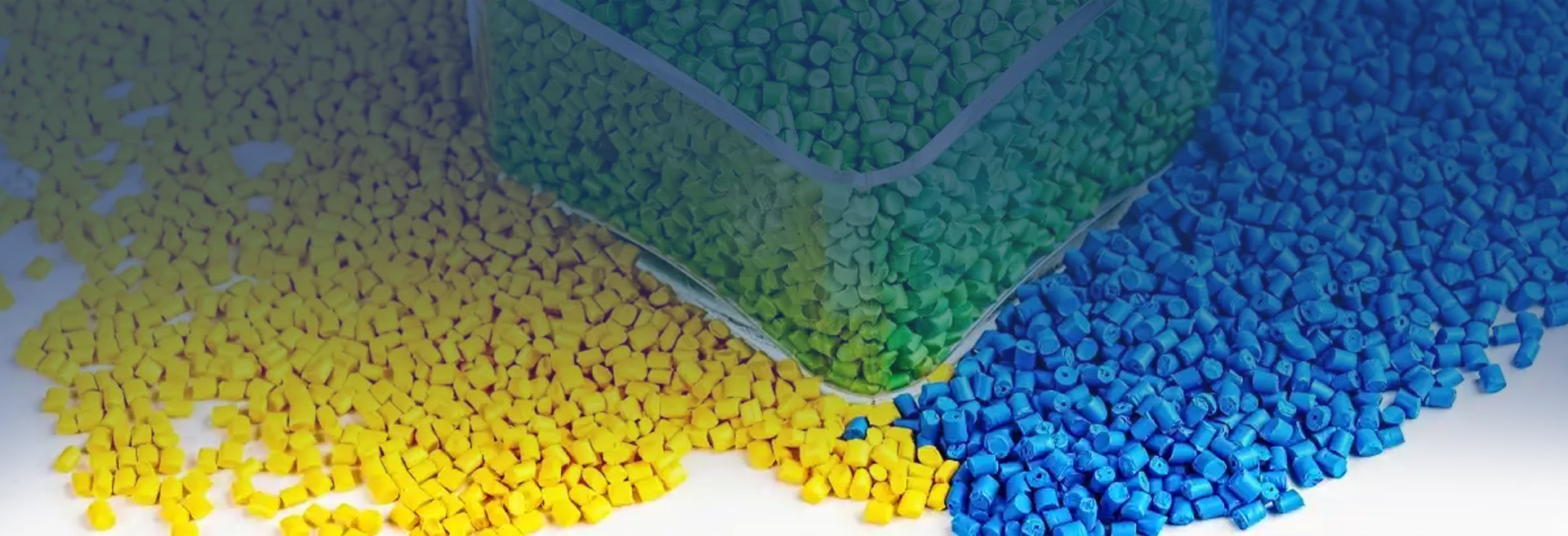

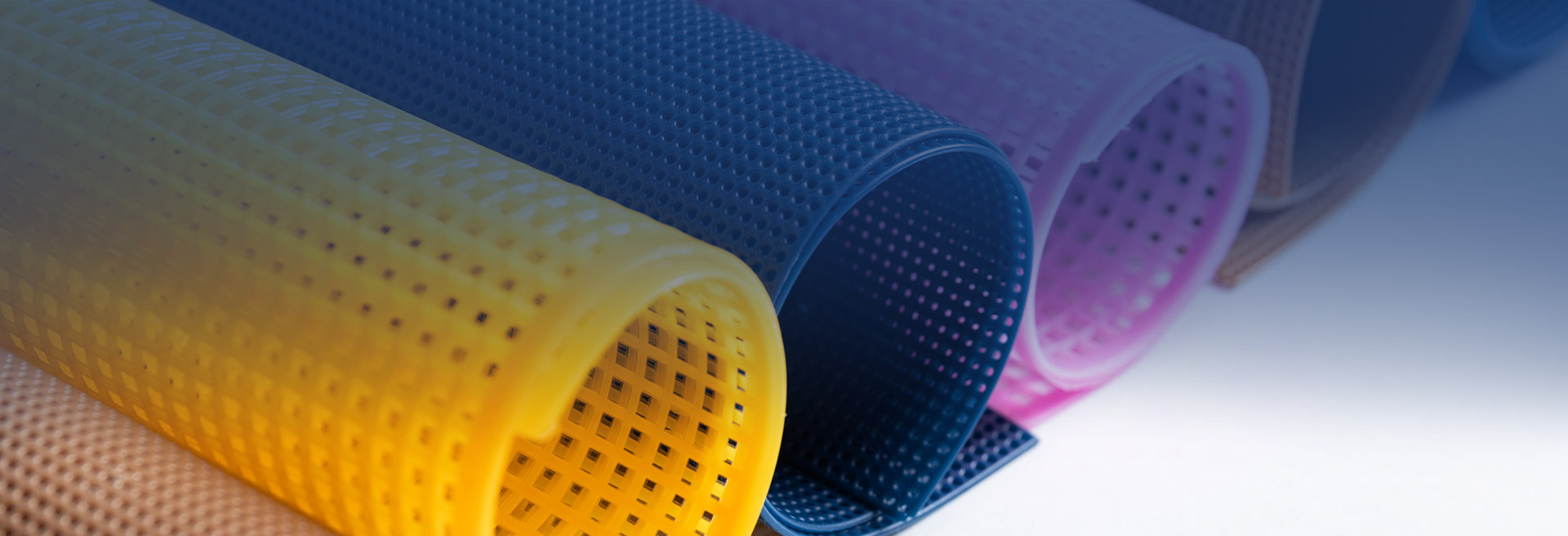

Products

High cost-effectiveness, worry free after-sales service

Our service advantages

High cost-effectiveness, worry free after-sales service

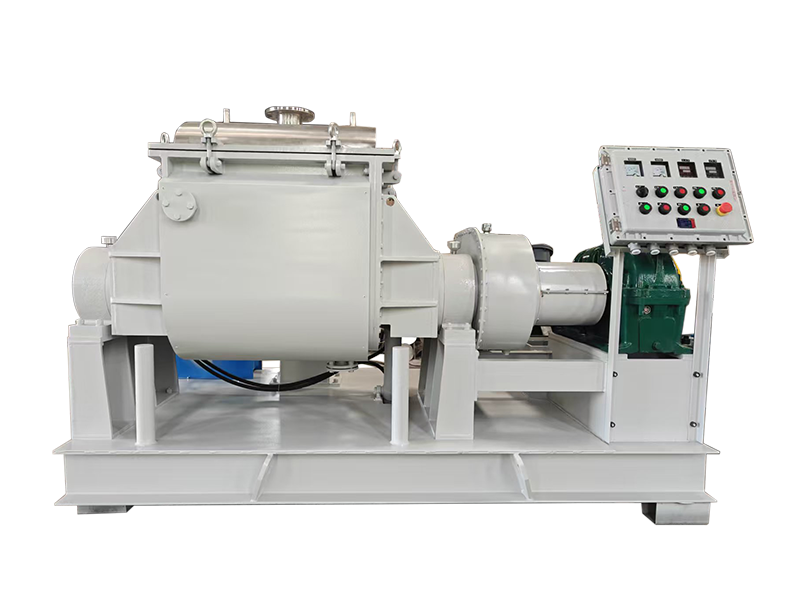

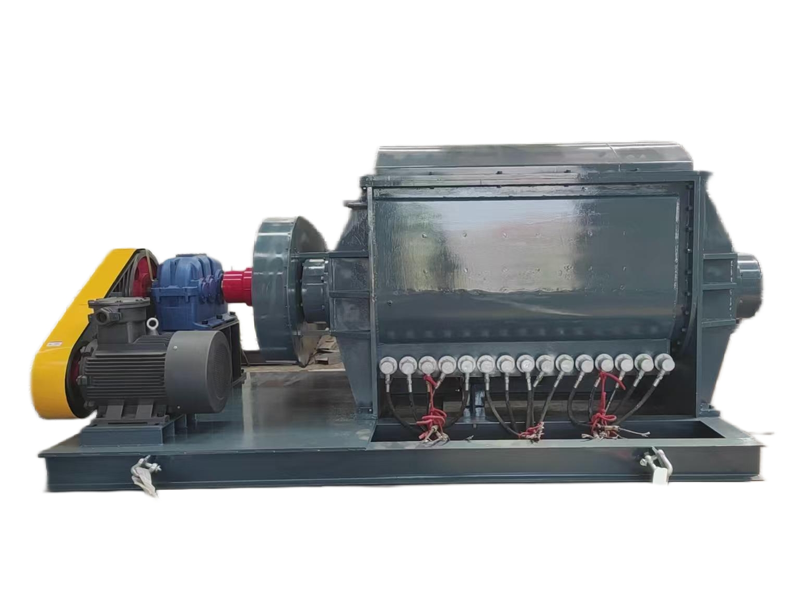

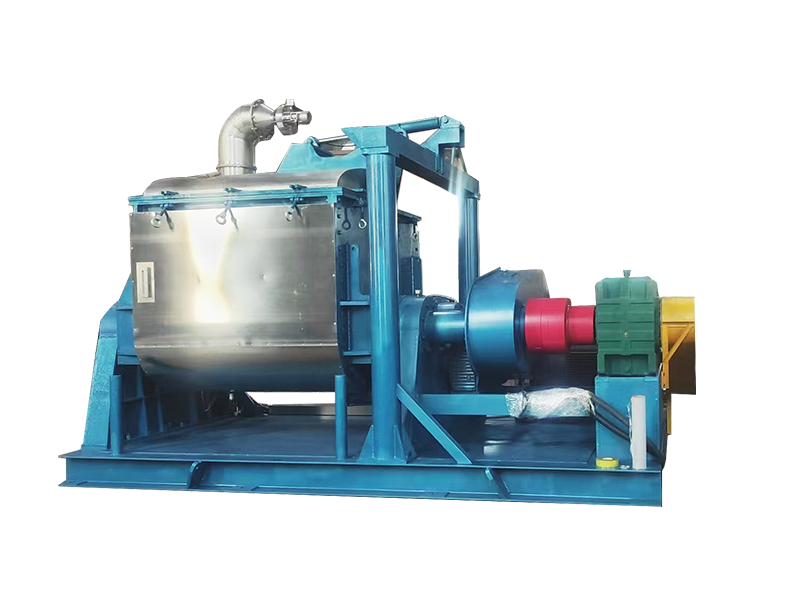

Specializing in the production of various types of kneader

Specially customized according to the material

Reasonable configuration, energy-saving and load reducing

Unique craftsmanship, attention to details

Fully tested and of satisfactory quality

Worry free after-sales service, complete accessories

About Us

Laizhou Jiarun Machinery Co., Ltd. is a professional manufacturer of kneader that integrates scientific research and development, production and operation, and technical services. The main products include: various types of ordinary, heavy-duty, high-temperature, and zero distance (energy-saving) kneader. The product is widely used in inks, plastics, rubber, silicone rubber, pharmaceuticals, cellulose, carbon, bubble gum, ceramics, dyes, resins, coatings, adhesives, cosmetics, polymers, and various coloring materials. Different usage purposes can be made: vacuum, pressure, atmospheric pressure. Discharge methods: flipping cylinder, screw and series bottom discharge. The temperature control forms can be divided into: low temperature, high temperature, and water cooling.

We adhere to the corporate creed of honest service and customer first, guided by the market, continuously improving, producing high-quality products, creating advantages, and striving to exceed user expectations.

More

中文

中文 English

English