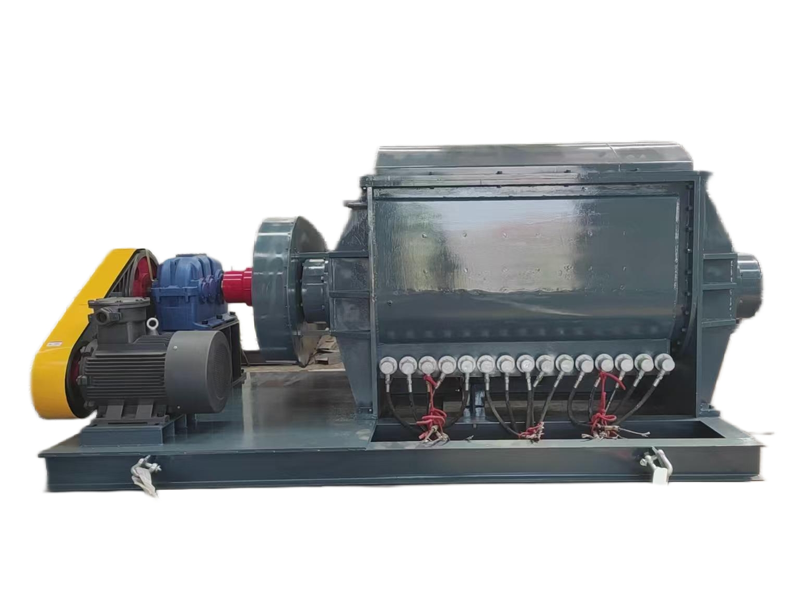

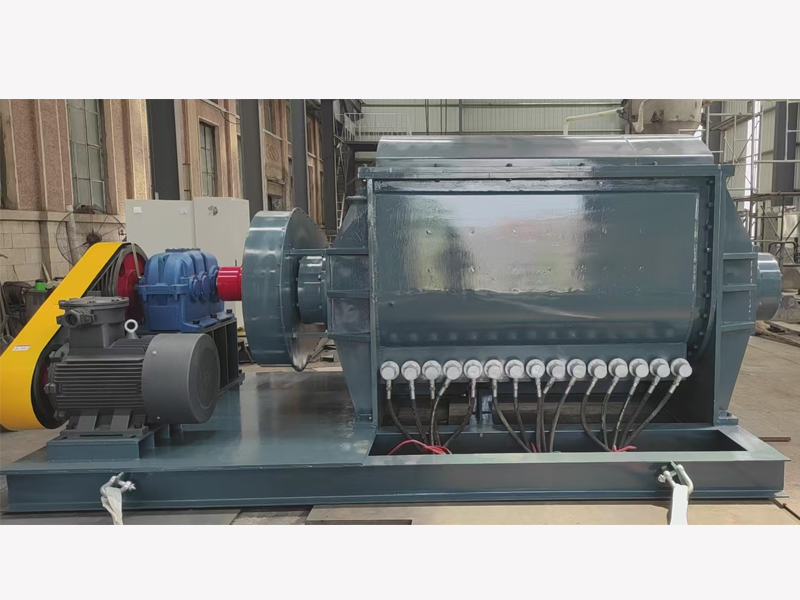

Carbon kneading machine

Carbon kneading machine is an equipment used in industrial and mining enterprises such as carbon, electric carbon, aluminum, graphite plants to produce various specifications of graphitized electrodes, electric carbon brushes, and blast furnace blocks. The equipment consists of six major modules, including kneading components and transmission systems. The cylinder body is made of stainless steel material and equipped with multi-mode temperature control systems such as electric heating and hydraulic flipping cylinder discharge methods. The mixing blade achieves shear mixing through forward and reverse rotation, and the blade is welded with wear-resistant plates to improve its service life. The jacket guide design optimizes heat transfer efficiency. Some models are equipped with hydraulic opening and closing covers and Harvard style sealing structures, supporting manual/automatic dual control operations, and equipped with temperature monitoring devices to prevent misoperation. Its double doors .

Technical parameters of kneader |

|||||||||||

| Model | JR5L | JR10L | JR100L | JR300L | JR500L | JR1000L | JR1500L | JR2000L | JR3000L | JR4000L | JR5000L |

| Volume | 5L | 10L | 100L | 300L | 500L | 1000L | 1500L | 2000L | 3000L | 4000L | 5000L |

| Heating method | 1. Thermal oil heating 2.electric heating 3. steam heating | ||||||||||

| Host power(KW) | 0.75-1.5KW | 1.5-3KW | 4-11KW | 5.5-22KW | 11-45KW | 18.5-75KW | 45-90KW | 45-160KW | 45-160KW | 55-280KW | 90-355 |

| Screw motor power | 3—5.5 | 4—11 | 5.5—15 | 7.5—18.5 | 11—22 | 15—37 | 18.5—45 | 18.5—45 | 18.5—45 | ||

| Electric heating power | 1.8 | 4.2 | 12 | 18 | 36 | 45 | 54 | 72-84 | Can be customized according to temperature | ||

| vapor pressure | 0.2-0.4 | ||||||||||

| Load factor | ≦70% | ||||||||||

| Speed | 41/26 | 41/26 | 36/22 | 36/22 | 36/25 | 36/25 | 36/25 | 30/22 | 30/22 | 27/22 | |

| Degree of vacuum | ≦0.095Mpa | ||||||||||

| Discharge method | 1. Turning cylinder discharge, 2. Screw discharge, 3. Bottom discharge | 1. Screw discharge 2. lower discharge | |||||||||

| Equipment weight | 210-300 | 250-340 | 1100-1250 | 2000-2500 | 2800-3800 | 4200-4600 | 5200-5500 | 6400-6800 | 9000-9500 | 10000-11000 | 11000-13000 |

| Remarks | 1. Industry parameters are based on conventional design; 2. Customized according to material characteristics | ||||||||||

Message

Fill in your phone and email information, and we will contact you promptly to resolve your issue as soon as possible

中文

中文 English

English